-

Use: fermentation temperature control

Placement: mainly outdoor use

Refrigerant gas: R-410A

Glycol solution: 30% glycol, 70% water

-

Innovative configuration with finned coil evaporator immersed in the accumulation tank, specifically designed for industrial applications. This allows to operate with high flow rates and low pressure drops even with liquids containing impurities.

Scroll compressors guarantee high efficiency, excellent performance and high energy savings.

Wide operating limits: water inlet temperature up to +35 °C and outlet temperature down to -10 °C.

. Ambient temperature up to +46 °C and minimum down to -5 °C.They comply with the limits required by the ErP regulation, both for the SEPR HT (Tier 2 01/01/2021) and for the SEPR MT (Tier 2 02/07/2018).

The R410A refrigerant (ODP=0) allows optimum performance due to its better heat exchange properties.

The large storage tank allows the water outlet temperature to be kept constant, even in conditions of highly variable thermal load.

The IP54/ IP44 degree of protection makes this unit suitable for outdoor installations.Suitable for both atmospheric and pressurized hydraulic circuits

(up to 6 barg).Complete safety equipment: HP/LP pressure switches, phase monitor, anti-freeze sensors, level sensors, crankcase resistors and internal hydraulic by-pass.

-

Refrigerant R410A

Hermetic scroll compressors

High efficiency finned package evaporator, with copper tubes and aluminum fins, installed inside the hydraulic accumulation tank

Electronic expansion valve

Axial suction fans, sickle-shaped blades made of painted sheet metal or aluminum covered with polypropylene.

Air-cooled condenser (copper tubes / aluminum fins). Air filter

Inertial storage tank (design pressure 6 barg) complete with charge/discharge valve and pressure gauge

Hydraulic safety bypass between water outlet and water inlet

Conductive type electronic level sensor

High and low refrigerant pressure switches

Refrigerant pressure gauges

Parametric electronic controller IC208CX

Degree of protection: IP54 / IP44

Phase monitor

Crankcase resistors

-

P5 pump (5 barg)

Vertical centrifugal fans for indoor use

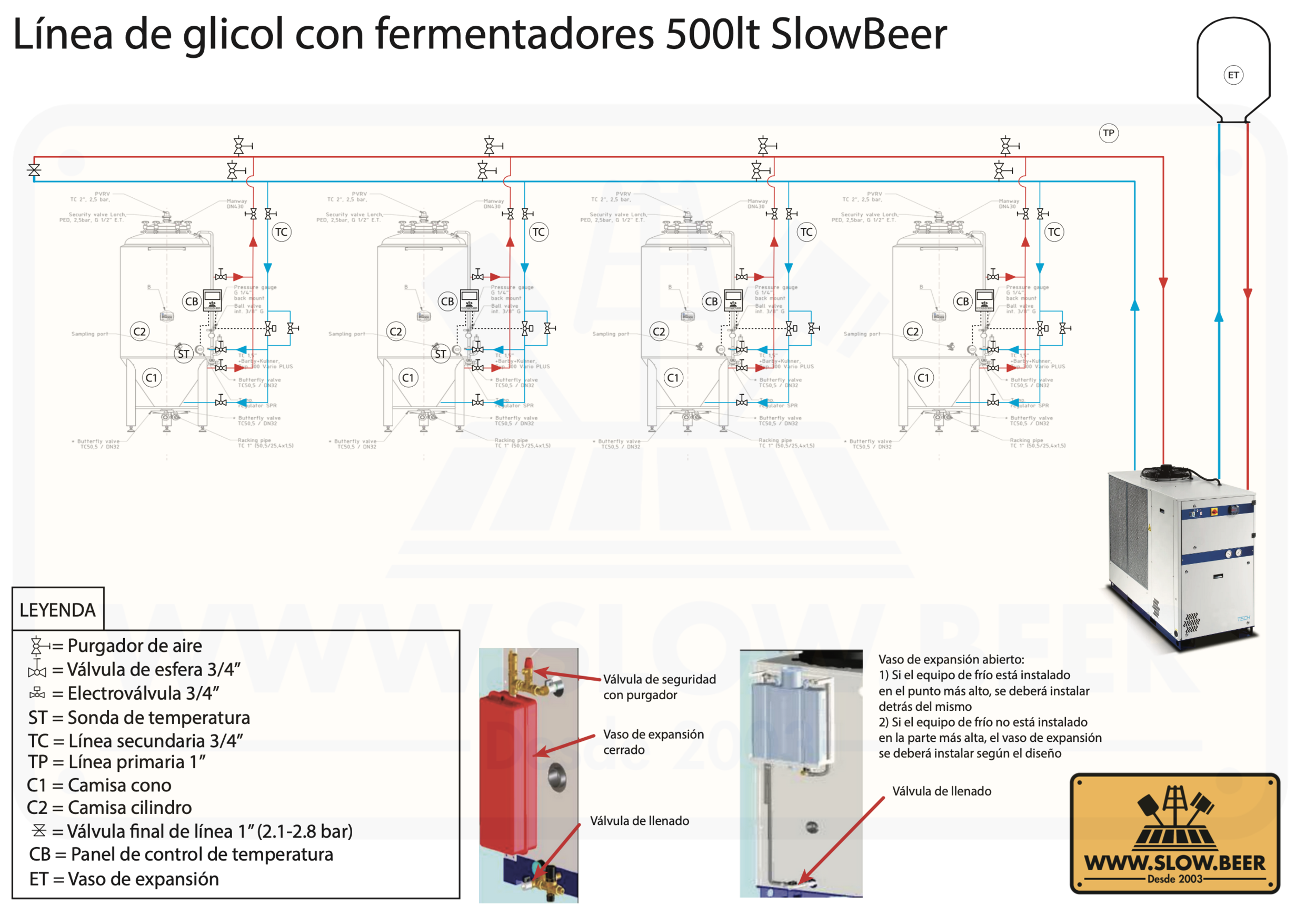

Temperature controller with probe and solenoid valve (1 x fermentor)

Food grade polypropylene glycol (25lt. carafe)

X series refrigeration equipment comparison sheet.

(*1) Data referred to normal operating conditions: ambient temperature 35 °C and evaporator water IN/OUT temperature 12/7 °C.

(*2) Weight in exercise.