-

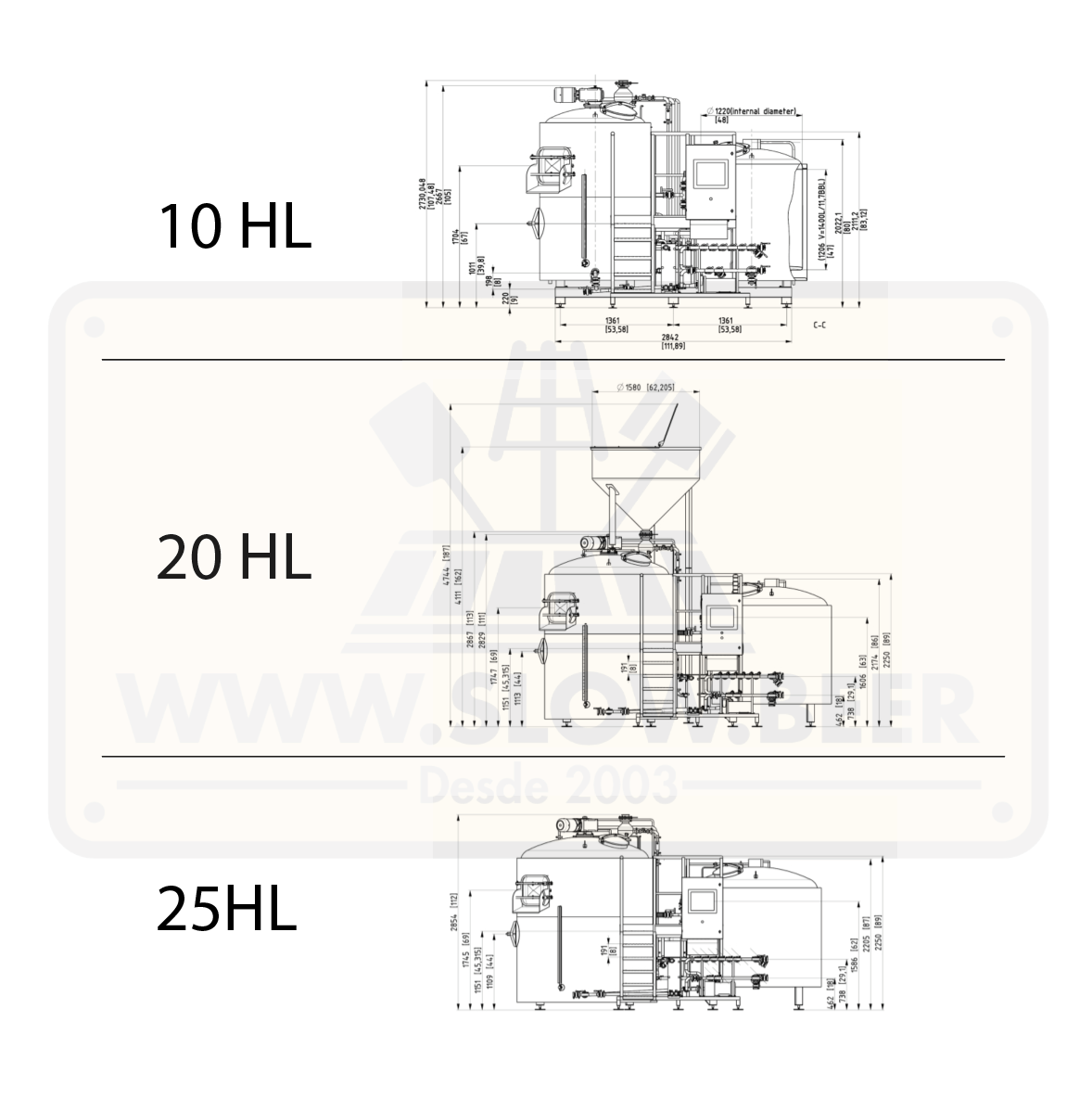

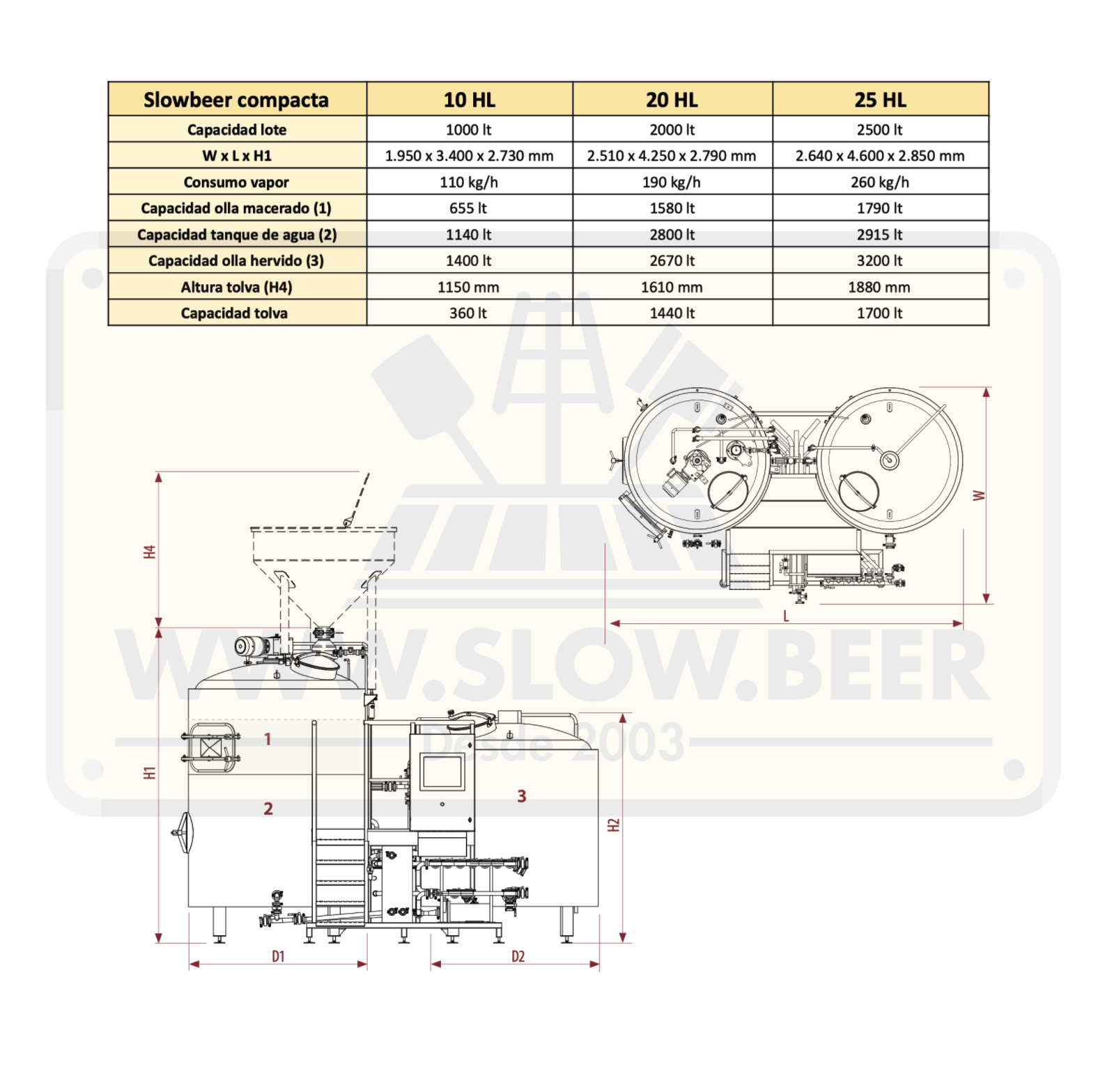

Capacity: 10HL / 20HL / 25HL

Heat source: steam (see comparative data sheet)

Dimensions: see comparative data sheet

Weight: see comparative data sheet

-

Yield >90%.

Steam heating system, no direct contact between wort and heating elements

Temperature rise of one degree per minute and a half, with minimum energy expenditure.

Homogeneous temperature in the baking tank due to heat distribution and insulation

Possibility of continuous firing, 4 firings per day

-

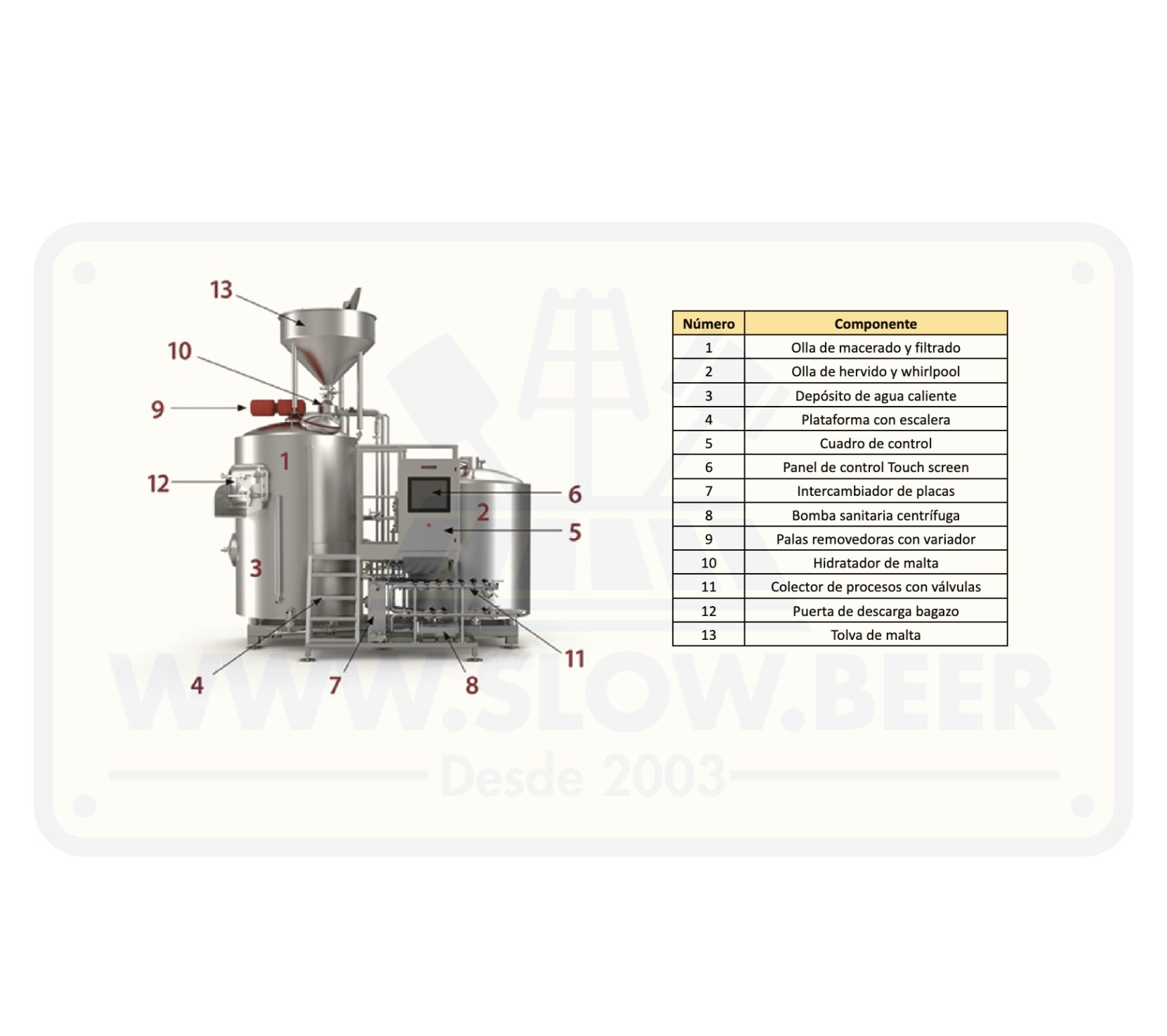

Maceration and filtration tank

Water tank

Hopper for malt hydration

Boiling vat and whirlpool

Centrifugal pump

Touch control panel

Plate heat exchanger

Process collector

Stainless steel support and platform

-

Steam condenser for boiling kettle / whirlpool

Hopper for malt 360lt / 1.500lt / 1.700lt

Connection pipes between firing room and boiler

Hot water tank 1200lt / 2000lt / 5000lt

Cold water tank 1200lt / 2000lt / 5000 lt

Slowbeer Plus 10/20/25HL models comparison sheet.

How is continuous firing performed?

Slowbeer Plus craft beer brewing equipment has two tanks . One of them has been designed for mashing and filtering, while the other one is in charge of boiling and whirlpooling.

The first tank (Mash/Lauter) then becomes free when the wort is transferred after lautering. This makes it possible to start a new beer production and to brew with continuous effect at the same time. While the first tank is mashing, the second is boiling.

Peninsula Brewery - Madrid

Specific component characteristics:

-

Material: AISI 304 stainless steel with SB finish exterior, mirror polished interior

Capacity: see comparative data sheet

Electric agitator with speed reducer

Temperature control by PT1000 probe

Steam heating, 2 independent zones bottom and jacket

Insulation with rock wool in the ferrule and bottom of the vessel

Conical bottom for good evacuation

Top lid with half-moon opening to inspect the wort

Diffuser for spraying

CIP cleaning ball

False bottom filter

Bagasse discharge gate

-

Material: AISI 304 stainless steel with SB finish exterior, mirror polished interior

Capacity: see comparative data sheet

Steam-heated with a jacket system

Insulated with rock wool

-

Material: stainless steel AISI 304

Tri-Clamp connection

-

Material: AISI 304 stainless steel with SB finish exterior, mirror polished interior

Capacity: see comparative data sheet

Temperature control by PT1000 probe

Steam heating, 2 independent zones bottom and jacket

Insulation with rock wool in the ferrule and bottom of the vessel

Conical bottom for good evacuation

Top lid with half-moon opening to inspect the wort

CIP cleaning ball

Condensation vapor outlet

Tangential inlet for whirlpool

-

Driven by a 0,37kW motor

Continuous speed control, with frequency inverter (by touch panel)

Material: stainless steel AISI316.

Function: processing and cleaning process (CIP)

-

Stainless steel case

Protective switches and fuses

PLC touch screen programmable with temperatures and times, pump and stirrer control

Electrical connection: 400V/50hz/3PH

-

2-stage cooling system (water and glycol)

Material in contact with the wort: stainless steel AISI316

Temperature probe PT1000

-

AISI 304 stainless steel pipes and fittings

Manual butterfly valves

AISI 304 stainless steel food fittings

Backlit must viewer

-

Platform with ladder and handrail

Centralized design provides easy access to all working positions and connections, as well as a high degree of control and supervision of the entire production process.

Non-slip, washable surface provides a safe working environment and easy maintenance

Material: stainless steel AISI 304

Adjustable feet