-

Capacity: 250lt (double cooking 500lt)

Heat source: electricity (15kW three-phase 3/380/50hz+N)

Dimensions: 2200x900xh1500 mm

Weight: 380kg

-

Yield >90%.

The must is not in direct contact with the resistors.

Temperature rise of one degree per minute and a half, with minimum energy expenditure.

Homogeneous temperature in the baking tank due to heat distribution and insulation

Possibility of double cooking

Plug and play" cooking room, once connected to water and mains, it is possible to process

-

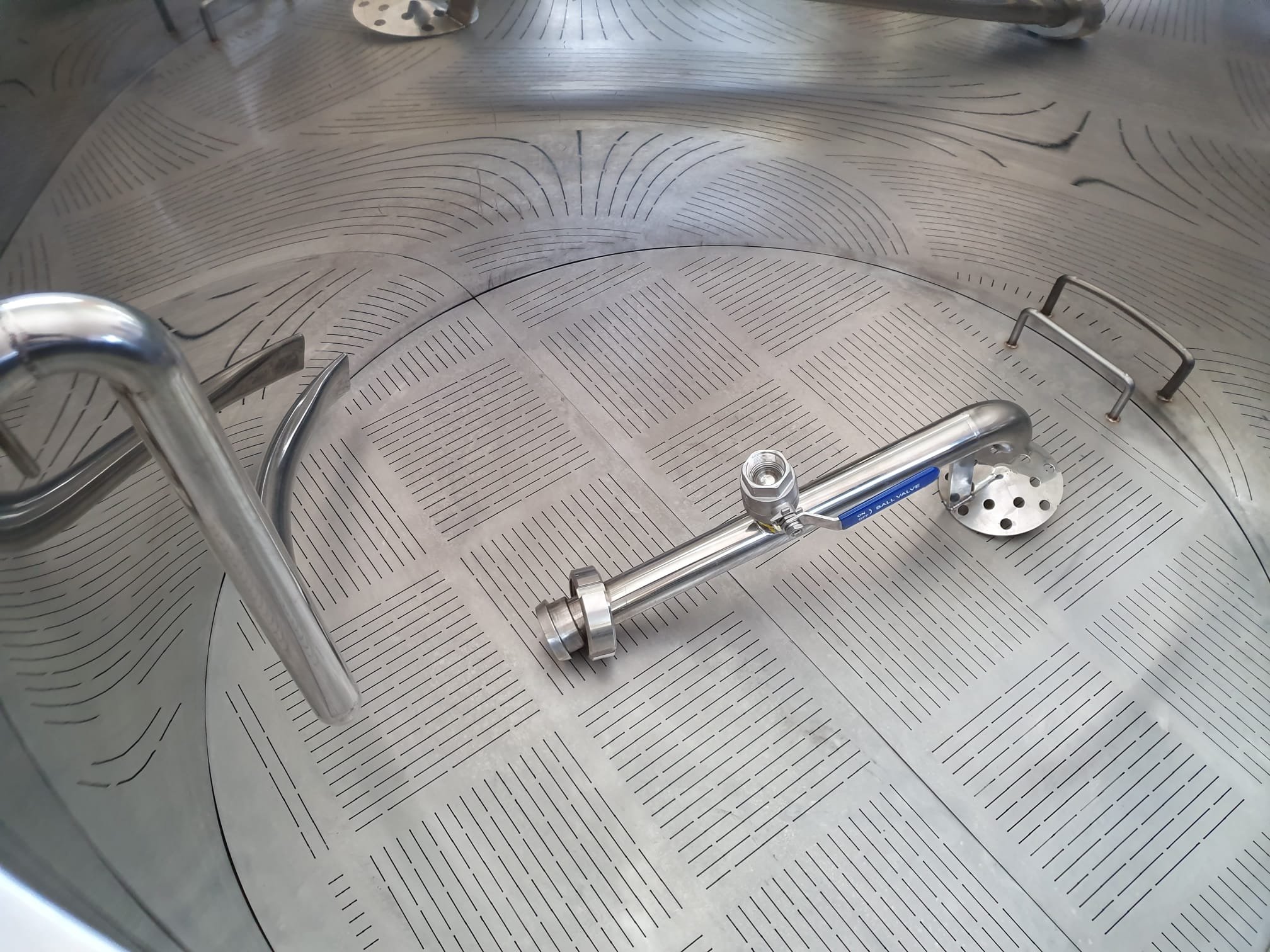

Mashing and boiling vat

Filter tank and whirlpool

Centrifugal pump

Touch control panel

Plate heat exchanger

Process collector

Stainless steel support

-

Steam condenser for mash/boiling vessel

Bagasse discharge gate

Hot water tank 600lt

Must oxygenator

Double stage heat exchanger

Specific component characteristics:

-

Material: AISI 304 stainless steel with SB finish

Capacity: 308 lt

0.37kW 2-blade electric stirrer with speed reducer

Temperature control by PT100 probe

Heating by electrical resistances at the bottom of the pot (12kW)

Insulation with rock wool in the ferrule and bottom of the vessel

Conical bottom for a good evacuation with discharge valve in center cone DN40

Top lid with half-moon opening to inspect the wort

Safety grille with CE-approved on/off system

Condensation vapors outlet ⌀ 100mm

-

Material: AISI 304 stainless steel with SB finish

3 mm thick, removable false bottom for filtration

Fully removable top cover

Conical bottom

Tangential inlet for whirlpool

Diffuser for spraying and washing with T inlet for water

Rock wool insulation jacket

Total and partial discharge DN40

-

1.1kW volumetric pump suitable for high temperatures

Continuous speed control, with frequency converter

Material: stainless steel AISI316.

Function: processing and cleaning process (CIP) -

Stainless steel case

Protective switches and fuses

Buttons and selectors: On/Off pump, On/Off stirrer, On/Off cycle start, 75%-100% power resistances

Inverter electric pump

PLC touch screen programmable up to 8 temperature steps

Thermostats with relay control

Thermostat for must temperature control at the exchanger outlet

-

1-stage cooling system

Material in contact with the wort: stainless steel AISI316

Temperature probe PT100 -

AISI 304 stainless steel pipes and fittings

Manual butterfly valves

DIN stainless steel AISI 304 stainless steel food connections

Must viewer

-

Material: stainless steel AISI 304

Adjustable feet