-

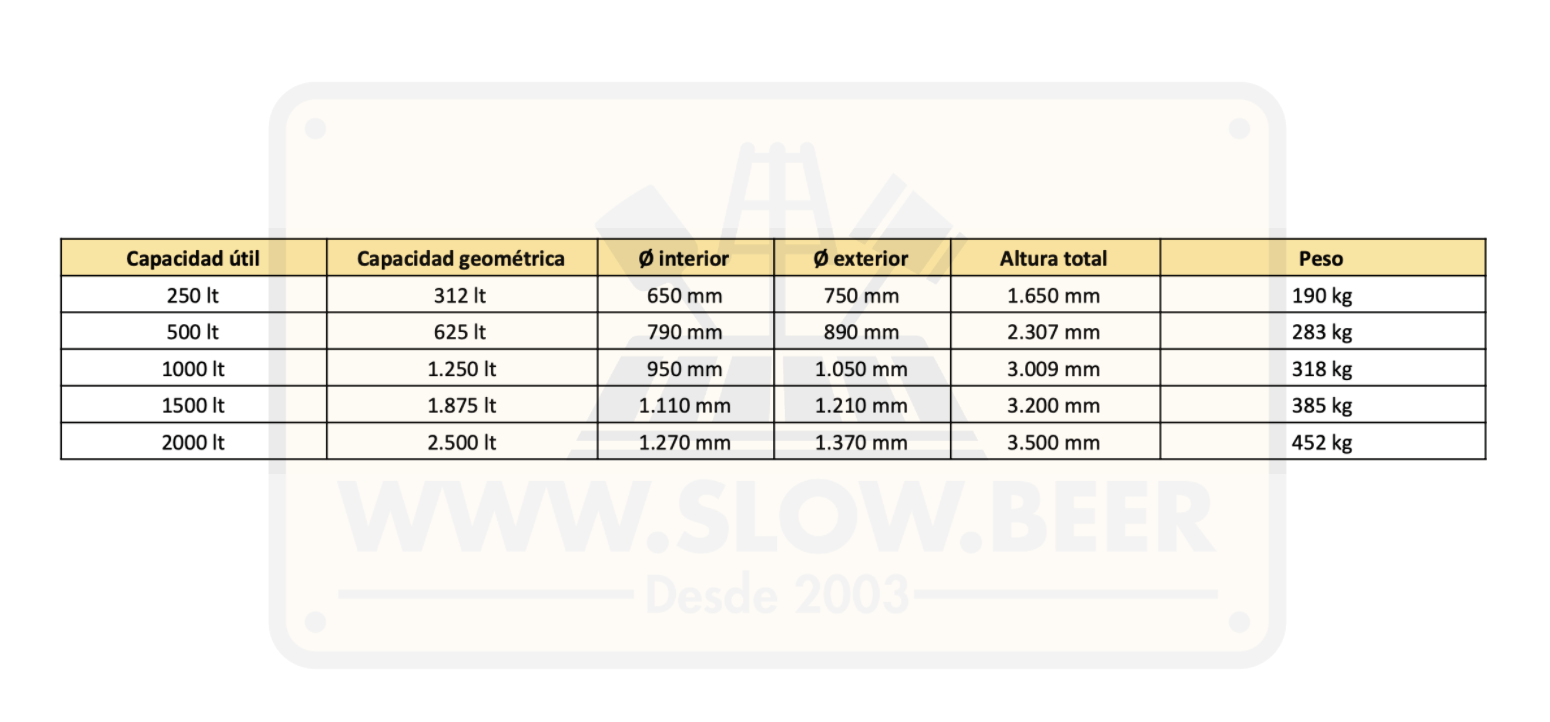

Useful capacity: from 250lt up to 2.000lt

Dimensions: see comparative data sheet

Weight: see comparative data sheet

Working pressure: 2 .5 bar (tested at 3.6 bar)

Material: stainless steel AISI304

-

Designed according to brewing technology: cylindrical-conical design, AISI304 steel

High quality finishes

Interior mirror polished finish 2R BA with roughness less than 0.8 μm

High energy efficiency

Delivered with PED certification, certificate of conformity and X-ray porosity test steel

Ready for use

-

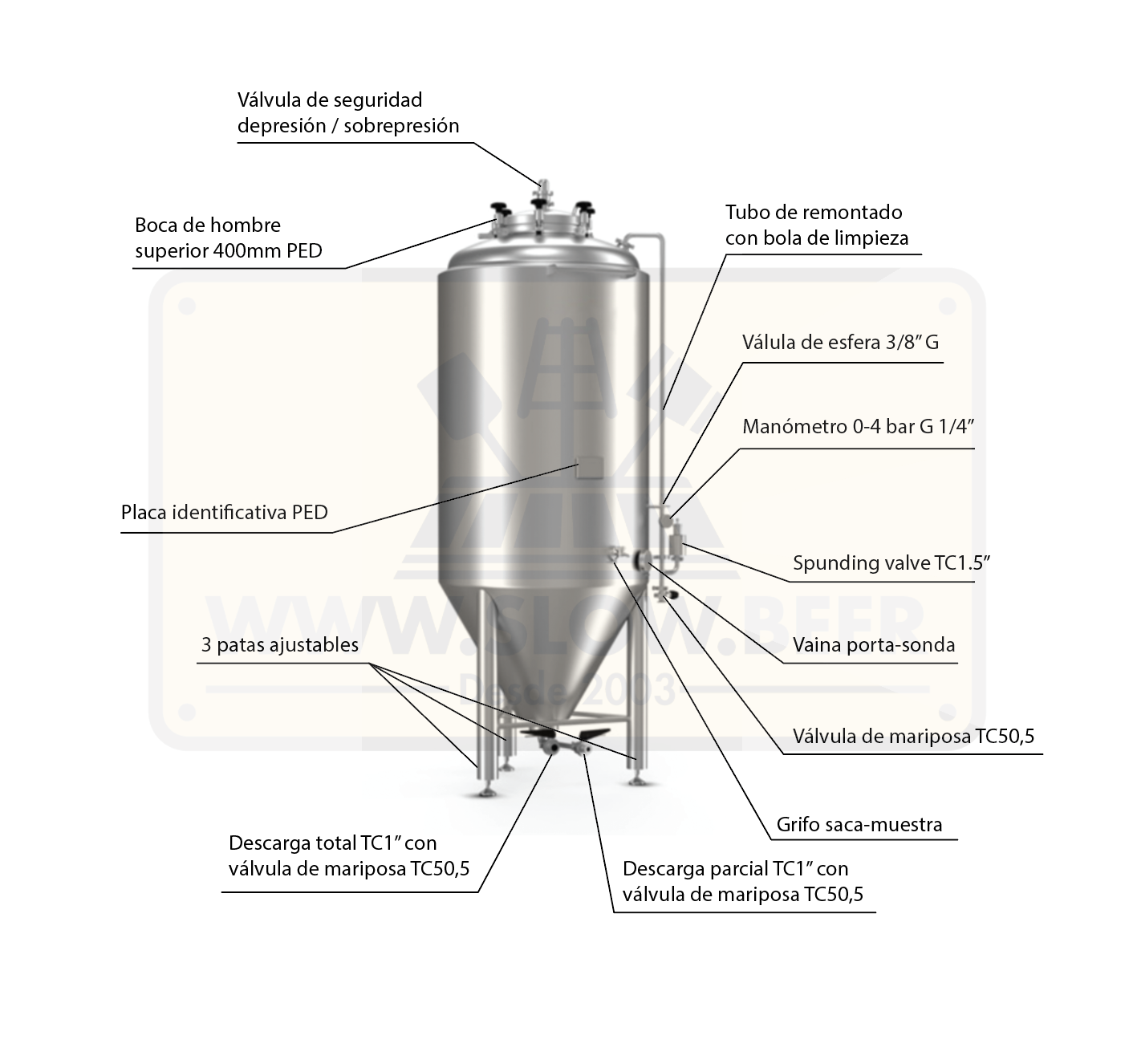

Adjustable AISI304 stainless steel legs with tubular connection

Nameplate with PED identification

Probe holder sleeve

Double jacket on cone and cylinder (working pressure 3 bar, test pressure 6 bar)

Expanded polyurethane thermal insulation

Boca de hombre superior 400mm PED

Rising main with 1" Tri-Clamp connection and butterfly valve

3/8" ball valve for CO2

Pressure gauge 0-4Bar

Spunding valve DN25

CIP cleaning ball

Partial and total discharge with butterfly valves TC 1.5".

Sampling tap

Documentation: technical drawings, maintenance and user manual, EU certificate of conformity for pressurized tanks according to PED directive (2014/68/EU), certificate of materials and components under pressure, warranty

-

DIN32 connections

Spiral sample tap

Temperature controller with probe and solenoid valve

Kit T con piedra porosa

Carbonation kit with antifreeze pressure gauge

Must viewer

Inline mechanical filter with 1 mm holes

Comparative data sheet of the isobaric PED fermenters currently in production.